Materials

Panerai commitment to innovation and technical expertise set the stage to innovative and high-tech materials,

enhanced every year through the research and development of the Laboratorio di Idee within the Manufacture in Neuchâtel.

Ceramica

Panerai’s Ceramic is a high-tech material derived from Zirconium Oxide powder, renowned for its strength and stability. Shaped through a complex process of working and finishing operations, it achieves a matte surface highly resistant to scratches, corrosion and heat.

25% lighter and 9 times harder than steel, it embodies Panerai’s pursuit of enduring performance and refined design.

Discover PAM01460 – The first ever Luminor Ceramica 40mm

Titanium

Lightweight yet incredibly strong, titanium is a defining feature of the PAM03325. This Grade 5 titanium case offers the strength of steel while being significantly lighter, enhancing comfort on the wrist. Highly resistant to corrosion, it is ideal for extreme conditions, reinforcing Panerai’s legacy in marine exploration. The brushed finish adds a rugged elegance, while its durability ensures longevity. This material choice reflects Panerai’s dedication to performance-driven innovation.

Discover the watches

Panerai Ti-Ceramitech™

Behold Ti-Ceramitech™, Panerai merges titanium's lightness with ceramic's resilience through a titanium ceramization process, resulting in a new patent application with a distinctive blue hue.

It's an innovative leap, 44% lighter than steel with a fracture toughness 10 times higher than ceramic.

Discover the watches

Bronzo

Bronzo is a material which owes its charm to the aged look it develops over time, giving every watch its peculiar character.

Its distinctive appearance is suggestive of the sea world to which Panerai is historically linked.

Discover the watches

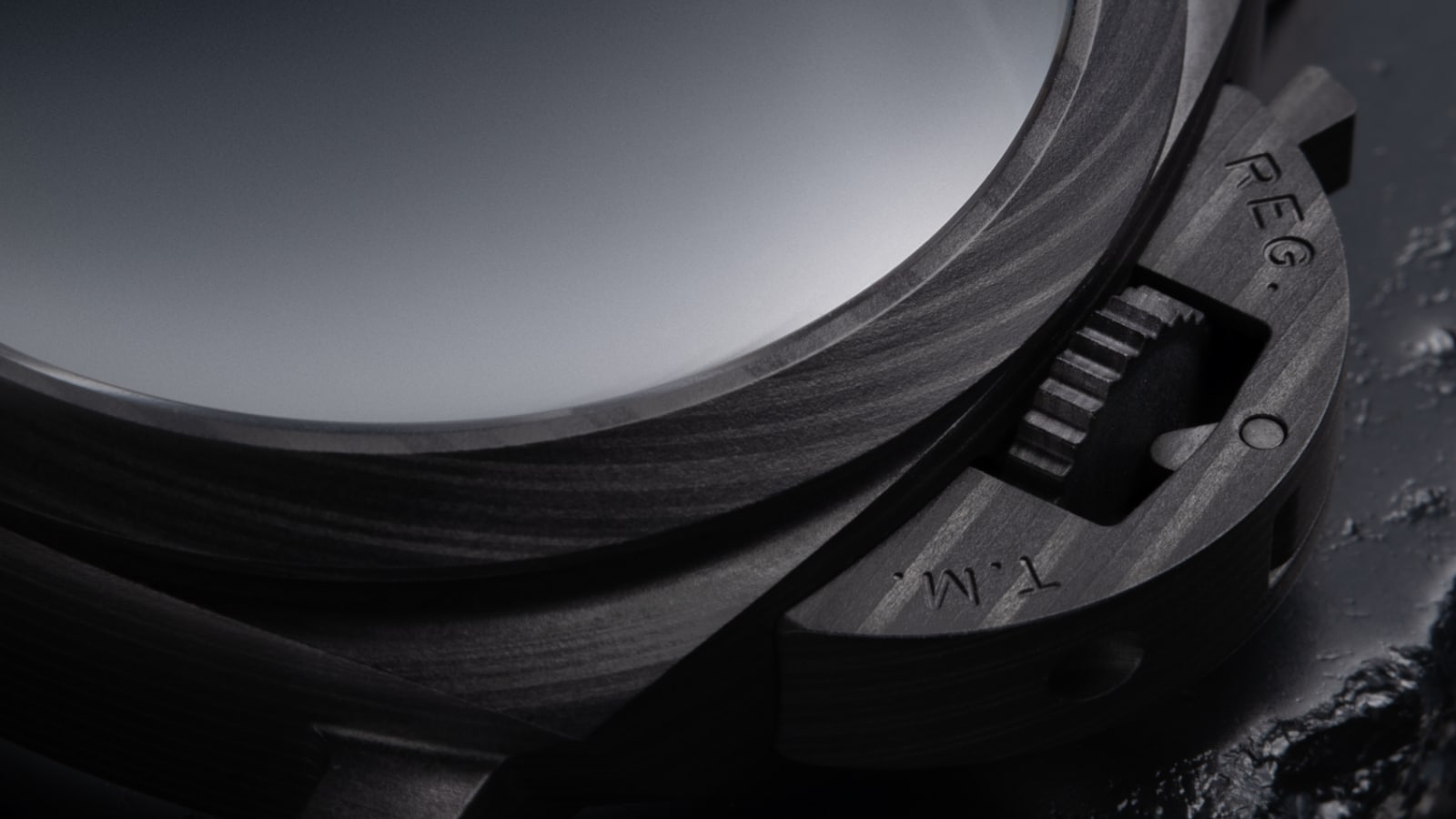

Panerai Carbotech™

Panerai Carbotech ™ is the lightest materials in Panerai’s rich assortment.

With a composite structure made of high performing long carbon fibers, the material has a distinctive design, giving each watch a peculiar character.

Discover the watches

Panerai Goldtech™

Panerai Goldtech™is a special gold alloy with an intensely red shade.

With a distinctive usage of copper and platinum, the material is in fact harder and more resistant than standard pink or yellow gold.

Discover the watches

Panerai Platinumtech™

Developed exclusively by Panerai, this special alloy is 80% harder than regular platinum.

With a specifically engineered treatment process, the material offers a higher scratch resistance.

Discover the watches

Panerai BMG-Tech ™

Panerai BMG-Tech ™ is a metallic glass made from a special alloy for exceptional robustness.

Its resistance to corrosion, external shocks, and magnetic fields ensures the watch remains virtually unchanged over time.

Discover the watches

Steel

Panerai's steadfast commitment to strength and reliability shines through steel usage. For today's cases it’s used AISI 316LVM grade 1.4441 stainless steel for its superior resistance to corrosion and its readiness for adventure.

Discover the watches