Movement Components Production

The Panerai Manufacture can itself produce the majority of the original components of the movements of its watches. Continuous technical updating and the use of increasingly advanced equipment enables the Panerai Manufacture to achieve a remarkably high and continually growing level of vertical integration.

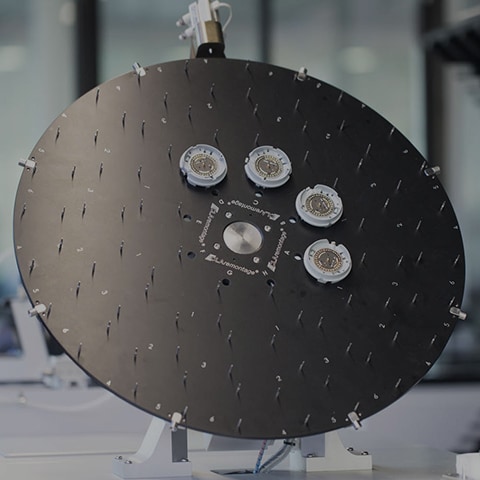

An area of 800 square metres on the ground floor of the building is devoted to machines of the latest generation, by means of which Panerai’s technical experts can transform the initial raw materials into bridges, plates and other components.

The precision required for these operations is extreme – the tolerance being of the order of microns – and the machines are programmed to carry out works of the highest complexity, with production cycles which may be unusually long in order to achieve the complicated geometry of the components perfectly.

The processes of perfectly machining the individual components to the shapes and dimensions required are followed by the operations of washing and galvanic treatment. The pieces are then given the elegant finishes – which include laser engraving, perlage, anglage and sandblasting – which are among the distinctive features of high quality watchmaking. The decorations may be minimalist or very sophisticated, varying from component to component, and they help to make each calibre a little masterpiece of micro-mechanics, technically perfect and aesthetically striking.

OFFICINE PANERAI MANUFACTURE CHAPTERS:

Movement and watch assembly

quality tests and controls

After sales service