Quality Tests and Controls

The technical characteristics of Panerai watches, historically designed for use under the most extreme conditions, are continuously subjected to rigorous quality control and testing in order to guarantee even higher standards than those required by the regulations of the sector.

All the inspections undertaken are designed to ensure the greatest reliability and durability of every Panerai watch, both under standard environmental conditions and when interacting with external agents which may be damaging, such as shocks, wear, extreme temperatures, acids, UV radiation and magnetic fields.

A timepiece which historically was created for use by professional divers must of course be completely resistant to water penetration and, to pass the tests, all Panerai watches must have a water-resistance more than 25% higher than the officially declared limits, from a minimum of 3 bar to a maximum of 250 bar (equivalent to a depth of about 2,500 metres) in the case of the most extreme Submersible models.

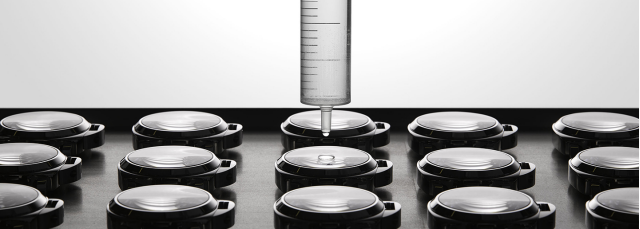

Panerai’s strict testing standards also include the “water drop” test, which is on the face of it simpler than tests carried out using sophisticated machinery but is in fact very revealing: this is carried out by heating the case and placing a drop of cold water or a cold external element on the surface of the crystal which protects the dial.

OFFICINE PANERAI MANUFACTURE CHAPTERS:

MOVEMENT COMPONENT PRODUCTION

Movement and watch assembly

After sales service